Maximising External Temperature Control: Key Considerations and Equipment Features

What is an external temperature application?

There are two types of temperature applications, internal and external. An internal application is when whatever you want to heat or cool is placed directly into the temperature controllers bath tank. With an internal application, the temperature control unit (TCU) serves as the vessel for heating and cooling. With an external application, temperature application is taking place away from or outside the TCU itself.

External applications can take many forms, including:

- Heating or cooling samples in an external vessel like a bioreactor

- Simulating temperatures or heating/cooling objects

- Removing heat generated from chemical or biochemical processes

Equipment and Processes that Use External Temperature Control

Much equipment and chemical/biochemical processes require careful temperature monitoring and management. Fermentation generates additional heat during the metabolic stages, and that heat needs to be removed to protect the sample environment and process. Equipment such as large-scale industrial lasers also generate heat that has to be removed to preserve the stability of the beam itself. Learn more about our cooling solutions.

Temperate control units pair with various types of equipment for external temperature control, including but not exclusive to:

- Lasers

- Fermenters

- Vacuum chambers

- Refractometers

- Polarimeters

- Rotary evaporators

- Spectrometers

- Electrophoresis

- Reaction calorimeters

- Extruders

- Moulding machines

A variety of chemical and biochemical processes may require external temperature control, including:

- Fermentation

- Distillation

- Condensation

- Flow Chemistry

- Material testing

- Component testing

- Sub-assembly testing

- Solvent evaporation

- Viscosity testing

- Dissolution testing,

- Crystallization

External Temperature Control Equipment and What You Should Look For

There are specific considerations that are required when choosing a temperature control unit for an external applications. Many basic chillers, heating or refrigerated/heating circulators operate on internal temperature control. Internal temperature control units use a temperature sensor inside the unit to measure and achieve the target temperature. These are not recommended for external temperature control because the actual temperature in the application can differ significantly from the displayed internal temperature measurement. Various factors contribute to this, including tubing length, insulation, etc. Using a TCU with internal-only temperature control can lead to a lot of trial and error, longer processing timelines, and poor results.

Things to Consider

Does the TCU have Pt100 and External Sensor Capabilities?

There’s one simple thing to look for when sourcing a TCU for external temperature control. Can you easily connect an external sensor such as a Pt100 sensor or thermocouple? The JULABO’s Temperature Control Units incorporate a LEMOSA 4-pin outlet for Pt100 sensors. These outlets allow you to plug one end of the Pt100 sensor into the unit and place the other end (the end with the sensor) directly into the application, providing you with an accurate measurement within the application itself. The unit will be able to control and monitor the application of the external Pt100 sensor. The TCU will then be able to control and monitor the application from the external Pt100 sensor. This eliminates any heat loss via tubing/plumbing, ensuring that the application reaches the required temperature.

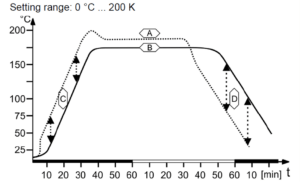

Band Limits

Temperature control units that are optimised for external temperature control provide a feature for band limits. If the application has a limit on temperature delta between fluid and application temperature, setting a band limit can protect the application from thermal stress. For example, jacketed glass reactors have a max. temperature differential across the internal glass wall that ranges from 50K to 80K. The JULABO units include a band limit value available to set appropriately for heating and cooling. Another way to visualise, think of band limit as thermal cruise control. The unit will not exceed the band limit value (the internal and external temperature difference), thus protecting the application from thermal stress.

Legend:

- Internal Bath

- External System

- Upper Band Limit

- Lower Band Limit

Upper bandlimit active while heating; lower bandlimit active while cooling.

Get in Touch with Our Experts

Here at Lab Unlimited, we have the experts to help with your temperature control units. We provide JULABO products, which specialise in external temperature control. The PRESTO range is a highly dynamic temperature control systems incorporate a closed design ideal for external temperature control. We also can offer several other solutions that will suit your needs.

|

To find out more: |